Putian Core Co., LTD——Anqing Xinpu Electric Co., LTD La première phase du projet d'acier au silicium orienté a été mise en production avec succès !

Putian Core Co., LTD——Anqing Xinpu Electric Co., LTD

La première phase du projet d'acier au silicium orienté a été mise en production avec succès !

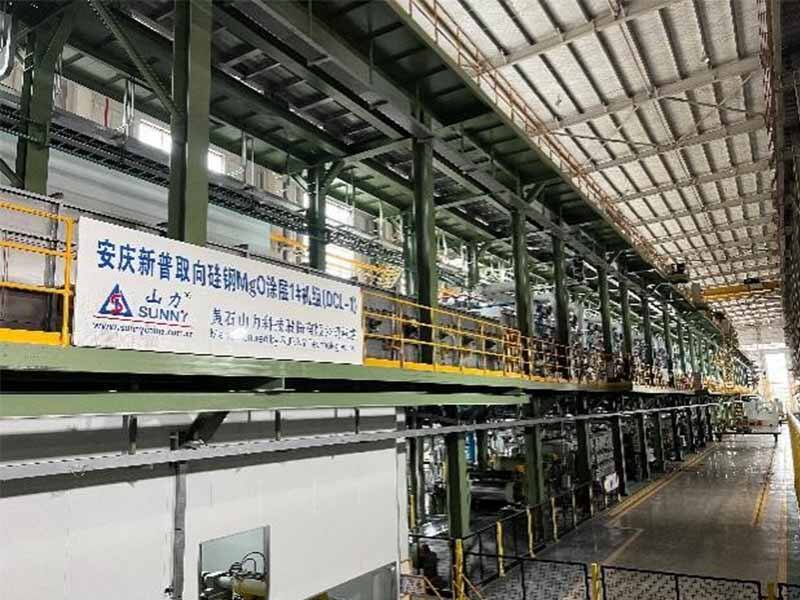

En mars 2023, la première phase de la ligne de revêtement de recuit n°1 en acier au silicium orienté (CGO) (DCL-1) et la ligne de revêtement par passage à chaud en acier au silicium orienté (CGO) n°1 (FCL-1) d'Anqing Xinpu Electric Co., LTD., sous contrat avec Sunny Technologies Incorporation Limited, ont été produits avec succès respectivement par un test de charge thermique d'alimentation unique ; L'objectif de production global du projet a été atteint début mai.

Anqing Xinpu Electrical Equipment Co., Ltd. est une filiale de Wuxi Putian Core Co., LTD. (appelé : Putian Core). Putian Core est une entreprise privée de haute technologie axée sur la fabrication, la recherche, le développement et la vente de noyaux de transformateur de puissance et la principale société de rédaction de la norme nationale GB/T32288 « Noyau en acier électrique pour transformateurs de puissance », et est également la société affiliée de Chine. Branche d'application principale de l'Association de l'industrie des équipements électriques. Le réseau de vente de produits et de services couvre de nombreuses provinces et régions autonomes à travers le pays et est exporté vers plus de 30 pays et régions tels que l'Amérique du Sud, l'Europe, le Moyen-Orient, l'Asie du Sud-Est, etc. Les produits ont été largement utilisés dans le réseau électrique national, centrale nucléaire, train à grande vitesse, métro, énergie solaire, énergie éolienne marine, grandes zones résidentielles et autres domaines. La production, les ventes et l’échelle maintiennent le leadership du secteur depuis de nombreuses années. Fournir un service de qualité unique et des solutions innovantes pour plus de 200 usines de transformation dans le monde. Anqing Xinpu Electrical Equipment Co., Ltd. a été créée pour fournir d'excellents produits CGO à la société mère.

Selon la technologie et l'équipement de Xinpu Electric, l'innovation des processus et la situation réelle du site, SUNNY dispose d'une ligne de revêtement par recuit d'acier au silicium orienté (CGO) « sur mesure » et d'une ligne de nivellement et de revêtement de tension thermique en acier au silicium orienté (CGO). Parmi eux, la ligne de recuit d'acier au silicium orienté (CGO) effectue le dégraissage de surface, le recuit et le revêtement de MgO sur la bobine d'acier CGO après le laminage à froid secondaire, avec une capacité de traitement annuelle prévue de 80,000 85,000 tonnes/an. La ligne de nivellement et de revêtement à chaud en acier au silicium orienté (CGO) élimine le MgO résiduel sur la surface du CGO provoqué par le processus précédent, puis effectue un décapage doux, un revêtement de la couche d'isolation, un séchage, un frittage et un nivellement à chaud, avec un capacité de traitement annuelle de XNUMX XNUMX tonnes/an. L'équipement et la technologie de base des deux lignes sont développés et conçus indépendamment par SUNNY, et les performances globales ont atteint le niveau avancé international.

Au cours de la mise en œuvre du projet, les deux parties ont travaillé ensemble pour courir contre la montre et établir une planification globale scientifique, ce qui a effectivement raccourci la période de construction. À l'heure actuelle, la deuxième phase du projet d'acier au silicium réalisé conjointement par les deux parties est en construction intense. SUNNY continuera à fournir à Xinpu Electric des services complets et de la plus haute qualité avec une technologie de pointe et une qualité haut de gamme.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NON

NON

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY