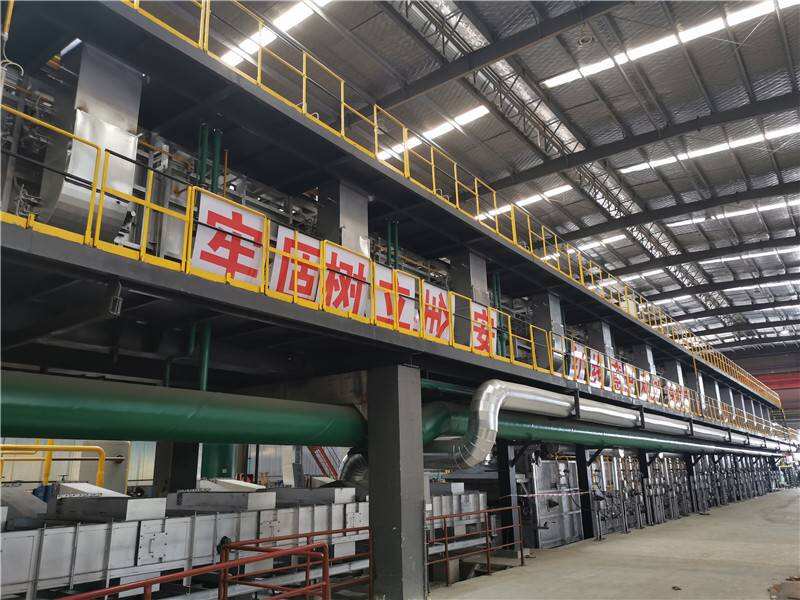

SUNNY shares successfully completed Zhongshan Zhongsheng Electric Steel's transformation line in 236 days

SUNNY Co., Ltd. worked hard for 236 days and successfully completed

Zhongshan Zhongsheng Electric Steel Transformation Line

On May 9, 2021, SUNNY Technology Co., Ltd. undertaken the original stainless steel processing line of Zhongshan Zhongsheng Metal Strip Technology Co., Ltd. in Zhongshan City, Guangdong Province. With the joint efforts of both parties, it has overcome the difficulties caused by the epidemic. In 236 days, it was successfully transformed into a continuous decarburization annealing coating unit (3# unit) for the production of non-oriented electrical steel, and the first volume of qualified electrical steel products officially rolled off the line through 3# unit.

In August 2020, Zhongshan Zhongsheng Metal Strip Technology Co., Ltd. (hereinafter referred to as Zhongshan Zhongsheng) in Zhongshan City, Guangdong Province, after seeing the epidemic, the market gradually improved, especially the market changes and soaring demand in the second half of the year. In order to seize this rare market demand opportunity, it is planned to decide on the strategic transformation of the company and transform the original stainless steel processing line. It has signed the first post-epidemic agreement with Huangshi Shanli Technology Co., Ltd. (hereinafter referred to as: Shanli Company). Through the transformation contract, and through the transformation, it can produce low- and medium-grade non-oriented electrical steel. The cold-rolled non-oriented electrical steel strip is degreased on the surface of the strip, and recrystallized and annealed in a protective atmosphere to grow the grains. Improve the magnetic level, eliminate stress, and coat the function of insulating layer. Its designed maximum processing capacity is 250,000 tons/year. The raw material variety is non-oriented electrical steel (50W470-50W1000), and the specification is 800mm-1250mm×0.35mm-0.65mm , With remote maintenance platform, front and rear double tension straightening arrangement, design unit process speed is Max.135m/min.

After Shanli Company as a domestic professional metallurgical engineering company undertook the project, under the conditions of tight contract period, heavy tasks, and difficult epidemic situation, all departments of the company worked together to formulate corresponding plans and all employees rushed to progress. In order not to delay the construction period, during January 2021, Shanli Company will send all the equipment to the site to avoid the inconvenience of transportation during the Spring Festival after the new year and affect the construction. After the Spring Festival on February 18 (the seventh day of the day), all construction workers will enter the site to start construction and installation of equipment. When the site foundation and auxiliary facilities are not fully equipped, try to do the work ahead, and finally start on April 15, 2021. Entering the commissioning stage, the commissioning schedule is 30 days, and it is scheduled to start production on May 15.

The success of this transformation line fully demonstrates the "Mountain Force Speed". It is also the embodiment of the cooperation of the core team and various departments of Shanli Company to meticulously serve Zhongshan Zhongsheng.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY