Products

Products

-

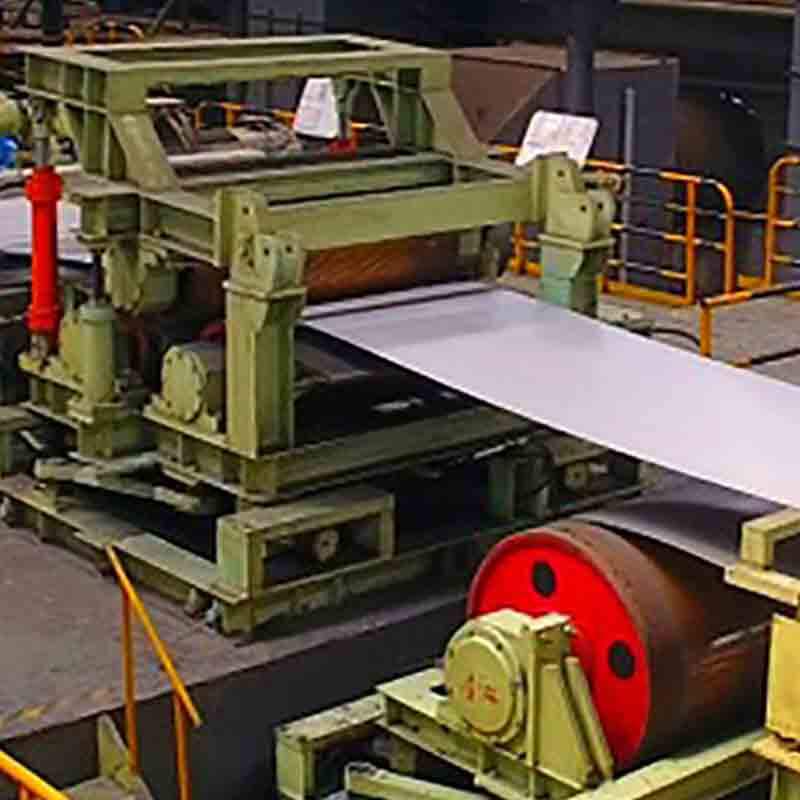

Micro cold rolling system solution SMICS

SMiCS (SUNNY Micro Cold Steel Complex Solution) integrates miniaturized pickling, cold rolling, galvanizing, color coating, degreasing, annealing, and finishing units to complete the production process from hot-rolled plates to cold-rolled end produ...

View More >> -

Carbon steel push-pull pickling unit (PPPL)

The push-pull hydrochloric acid shallow groove turbulent pickling process is used to remove the iron oxide layer on the surface of the hot-rolled steel strip and cut off the irregular edges of the steel strip to provide qualified hot-rolled plate raw m...

View More >> -

Carbon Steel Continuous Pickling Unit (CPL)

The continuous hydrochloric acid pickling process is adopted to remove the iron oxide layer on the surface of the hot-rolled steel strip and cut off the irregular edges of the steel strip to provide qualified hot-rolled steel materials for the next pro...

View More >> -

Continuous Galvalume Production Line (GL)

Hot-dip aluminum-zinc-silicon (GL) products are hot-dip aluminum (Al55%), zinc (Zn43.5%), and silicon (Si1.5%) alloys on the surface of strip steel, with excellent corrosion resistance. Hot-dip aluminum-zinc alloy is successfully developed on the ba...

View More >> -

Continuous Hot Rolled Galvanized Sheet Production Line (HGI)

Main features of the unit: Raw material: strip width: 600-1550mm, thickness: 1.5-4.0mm, hot-rolled low carbon steel coil after pickling, no oil or less oil. Plating type: GI, GA, GF; weight: 60-600g/m2 Product quality: in line with GB/T2518-2...

View More >> -

Continuous cold rolled galvanized sheet production line (GI)

Main features of the unit: Raw material: strip width: 600-1550mm, thickness: 0.2-1.2 (1.5) mm cold rolled low carbon steel SPCC, SPCD, FH, in line with JISG3141 Plating type: GI, GA, GF; weight: 60-300g/m2 Product quality: in line with GB/...

View More >> -

Continuous color coated board production line (PPGI, PPGL)

The strip steel continuous color coating unit is to re-coat the paint film on the (aluminum) zinc or aluminum plate substrate to achieve further anti-corrosion and beautification effects and expand the scope of use of the product. Main technical pa...

View More >> -

Continuous annealing line (CAL)

Steel strip annealing is to even out the chemical composition and structure of the steel, refine the grain, adjust the hardness, eliminate internal stress and work hardening, and improve the forming and processing performance of the steel. Continuo...

View More >> -

Stainless steel annealing and pickling line (CAPL)

I cold-rolled stainless steel annealing and pickling line The cold-rolled pickling and annealing process of stainless steel can be divided into intermediate annealing pickling and finished annealing pickling. The main purpose is to recrystallize the cold-rolled stainless steel after annealing to eliminate work hardening, so as to achieve the purpose of softening and improving mechanical properties. Pickling is used to eliminate impurities such as iron oxide scale produced in the annealing process and further improve the surface quality of the strip.

View More >> -

Cold rolled silicon steel continuous decarburization annealing line (CNGO)

Degrease the surface of the cold-rolled non-oriented silicon steel (CNGO), and perform decarburization annealing and recrystallization annealing in a protective atmosphere to reduce the carbon content of the strip to the specified range, so that the crystal grains will grow and the magnetic level will be improved , Relieve stress, and apply insulation layer.

View More >>

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY