Products

Cold rolled silicon steel continuous decarburization annealing line (CNGO)

Classification Solution

Degrease the surface of the cold-rolled non-oriented silicon steel (CNGO), and perform decarburization annealing and recrystallization annealing in a protective atmosphere to reduce the carbon content of the strip to the specified range, so that the crystal grains will grow and the magnetic level will be improved , Relieve stress, and apply insulation layer.

- Overview

- Inquiry

- Related Products

Degrease the surface of the cold-rolled non-oriented silicon steel (CNGO), and perform decarburization annealing and recrystallization annealing in a protective atmosphere to reduce the carbon content of the strip to the specified range, so that the crystal grains will grow and the magnetic level will be improved , Relieve stress and apply insulation layer.

The main technical parameters

Raw material: Non-oriented electrical steel (Si≤2.0%) cold rolled hardened steel coil W470-W1300

Strip carbon content: C≤50ppm

Strip thickness: 0.35-0.65mm

Strip width: 900-1250mm

Product: Electrical steel cold rolled coil

Representative specifications: 50W470-50W60050W800-50W1300

Quality Standard: GB/T2521-1996

Carbon content: C≤27ppm

Unit speed: Inlet 0-200mpm, process section, 0-135mpm, outlet section 0-200mpm

Annual output: 200,000tpy

Energy-saving method: Comprehensive utilization of waste heat recovery of exhaust gas, SUNNY patent

Continuous decarburization annealing furnace: Non-oxidizing heating (NOF) + full radiant tube heating (RTF), vertical and horizontal

Fuel type: Natural gas, liquefied petroleum gas

Decarburization Method: Continuous decarburization of protective gas

Insulation coating: Using roller coater + coating drying and curing

Welding equipment: Narrow lap seam welder

Degreasing form: Chemical degreasing + electrolytic degreasing + three-stage water rinsing, vertical or horizontal

Electrical control system: SIEMENS or ABB AC variable frequency automatic control system

Industrial automation: SIEMENS or ABB intelligent automatic control system.

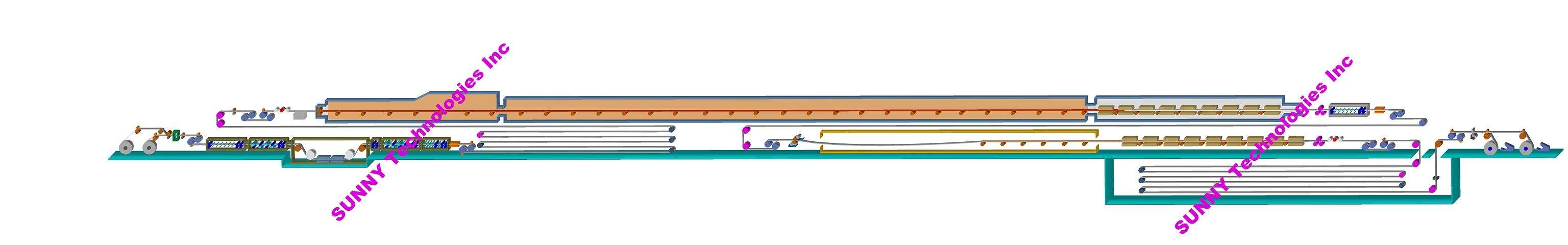

Main production process

Uncoiling→welding→degreasing (alkali spray→alkali scrubbing→electrolytic degreasing→hot water cleaning→drying)→decarburization annealing→cooling→insulating layer coating→sintering→cooling→surface inspection→splitting→coiling

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY