Products

Continuous color coated board production line (PPGI, PPGL)

Classification Solution

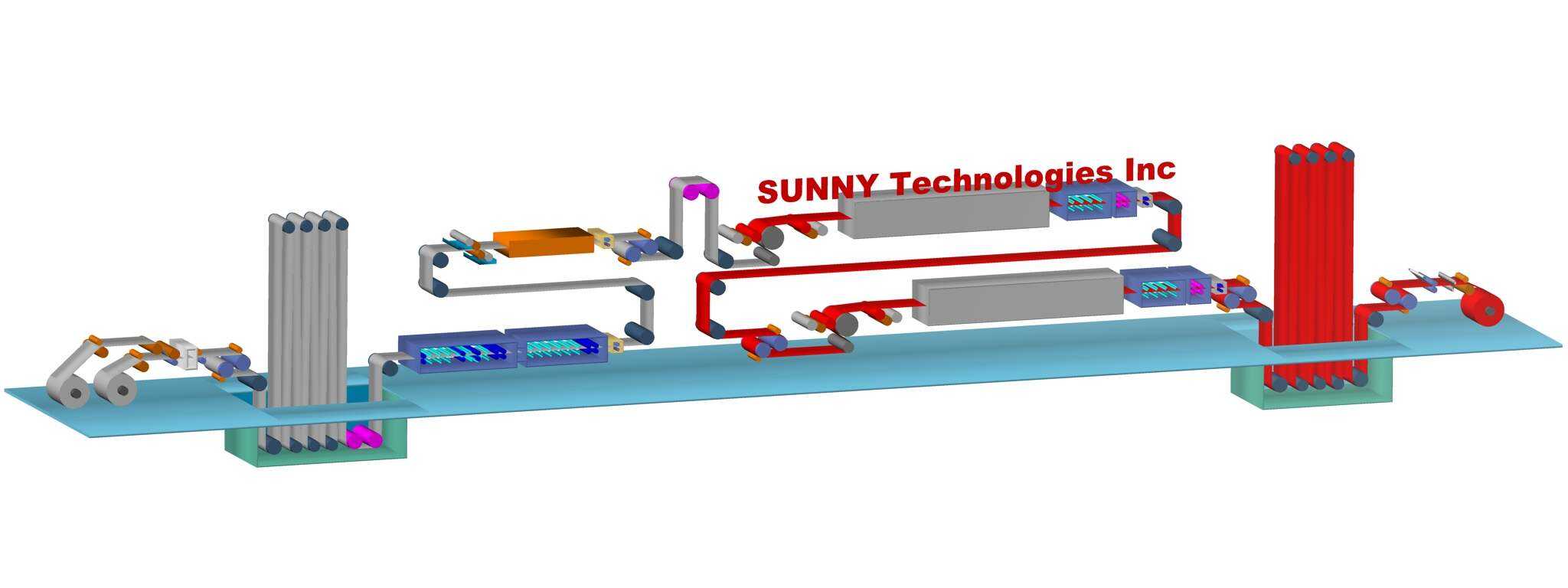

The strip steel continuous color coating unit is to re-coat the paint film on the (aluminum) zinc or aluminum plate substrate to achieve further anti-corrosion and beautification effects and expand the scope of use of the product.

- Overview

- Inquiry

- Related Products

The strip steel continuous color coating unit is to re-coat the paint film on the (aluminum) zinc or aluminum plate substrate to achieve further anti-corrosion and beautification effects and expand the scope of use of the product.

Main technical parameters of the unit:

Raw material: Galvanized steel coil (GI/GL), 800-1250mm×0.2-1.2mm

Unit process speed: 60-120mpm

Color coating process: Two coating and two drying (building materials board), three coating and three drying (home appliance board)

The coating machine is designed with adhesive roller, metering roller and coating roller, which can precisely adjust the thickness of the paint film.

Set up a curing furnace and waste gas incineration waste heat utilization system, use fresh air (high-quality products) or flue gas (low-cost) to dry and cure the paint film, and burn off the volatile solvents in the paint to achieve the effect of environmental protection and energy saving .

uses SIEMENS AC frequency conversion control system

adopt SIEMENS automatic temperature control system

The main process is as follows:

Uncoiling→sewing machine→cleaning→chemical coating→initial coating machine→curing→fine coating machine→curing→inspection→cutting→coiling machine

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY