Products

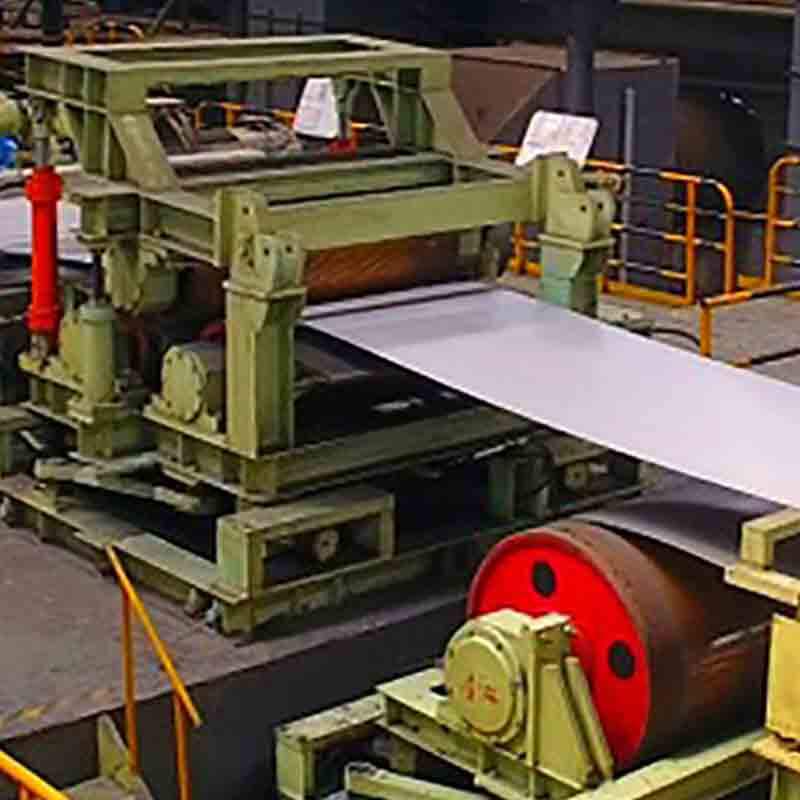

Continuous annealing line (CAL)

Classification Solution

Steel strip annealing is to even out the chemical composition and structure of the steel, refine the grain, adjust the hardness, eliminate internal stress and work hardening, and improve the forming and processing performance of the steel.

- Overview

- Inquiry

- Related Products

Steel strip annealing is to even out the chemical composition and structure of the steel, refine the grain, adjust the hardness, eliminate internal stress and work hardening, and improve the forming and processing performance of the steel.

Continuous annealing is the process of heating the strip steel to an appropriate temperature under a protective atmosphere and keeping it for a certain period of time, and then cooling and overaging treatment. In order to improve the surface quality of the strip, an online leveling machine is generally designed.

Main features of the unit:

Raw material: Strip steel: Width: 600-1550mm, thickness: 0.2-1.2 (1.5) mm

Material: Cold rolled steel coil SPCC, SPCD, SPCE, in line with JISG3141

Product quality: CQ, DQ and DDQ, in line with JISG3141

Unit speed: Inlet 0-240mpm, process section, 0-180mpm, outlet section 0-240mpm

Annual output: 100,000-300,000tpy

Energy-saving method: Waste heat recovery of exhaust gas, SUNNY patent

Continuous annealing furnace: Full radiant tube heating (RTF), vertical

Fuel type: Natural gas, liquefied petroleum gas, mixed gas, coke oven gas and electricity

Welding equipment: Narrow lap seam welder

Degreasing form: Chemical degreasing + electrolytic degreasing + tertiary water rinsing, vertical or horizontal

Smoothing machine: Four-roll wet smoothing, maximum rolling force of 6,000KN

Pull straightening machine: Two bending and two straightening (Optional)

Oiling method: Electrostatic oiling

Electrical control system: SIEMENS or ABB AC frequency conversion control system

Automation instrument: SIEMENS or ABB automation control system

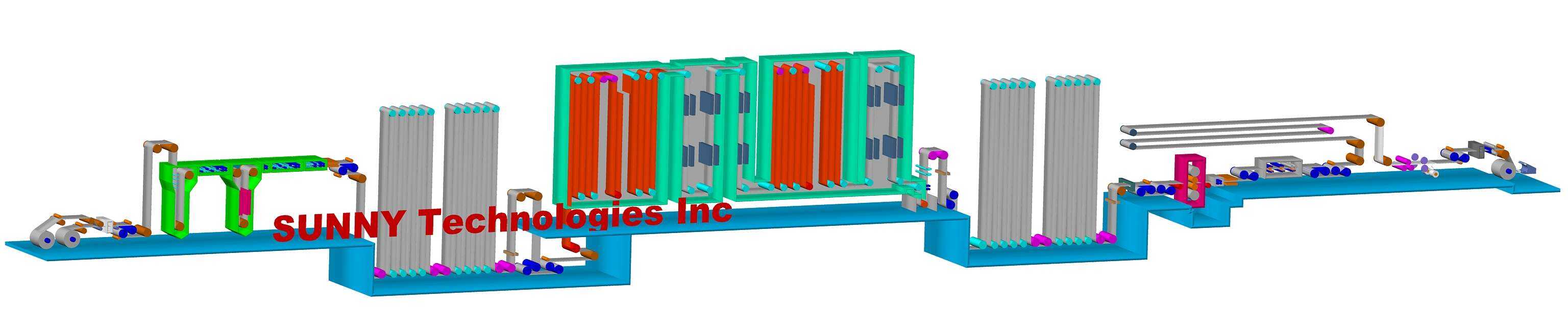

The main process flow of the unit:

'

'

Uncoiling → welding → degreasing (alkali washing + alkali scrubbing + electrolysis + water scrubbing + water cleaning) → annealing reduction (heating → soaking → rapid cooling → overaging → secondary cooling → water quenching → drying) → leveling → stretching → Trimming → Inspection → Oiling → Slitting → Coiling

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY